The Fab Academy 2014

Digital Fabrication Laboratory. Department of Architecture.

Institute of Technology. EPS-CEU San Pablo CEU University

Adolfo Gutiérrez Sánchez

Architect

The Fab Academy 2014 Digital Fabrication Laboratory. Department of Architecture. Institute of Technology. EPS-CEU San Pablo CEU University |

Adolfo Gutiérrez Sánchez Architect |

|||

| Home | Portfolio | Files | ||

| MECHANICAL DESIGN |

|

The assignment The assignment for this week was to add practice and do some mecanical design of our final project. My project has an special interest in mechanical design, as the chain and the gears have been completely designed using different techniques of the FabLab. I have not completed all the gears of my project, but I have realized that there is a very important fact in the funcioning: TENSION. My chain has to be very tensioned so the whole meechanism moves correctly. I will need to add more tension to the whole design in order it to work. |

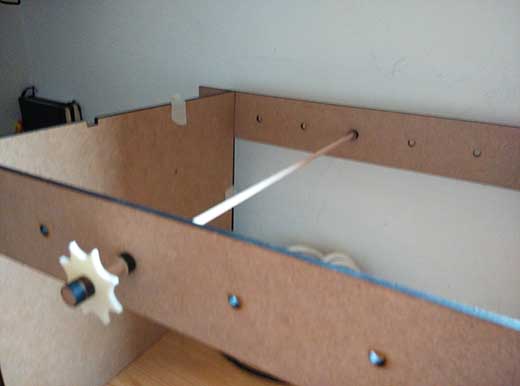

The needed pieces From the start of the FabLab, I have been trying to focus my assignments to my final project proposal, so I have used different techniques learnt during the course to build my mechanism: 1. Wood structure: as the wood I am using is not very thick (5 mm), I could cut it using the Laser Cutting, in order to save some time and I feel muh more comfortable with this machine.

|

|

|

|

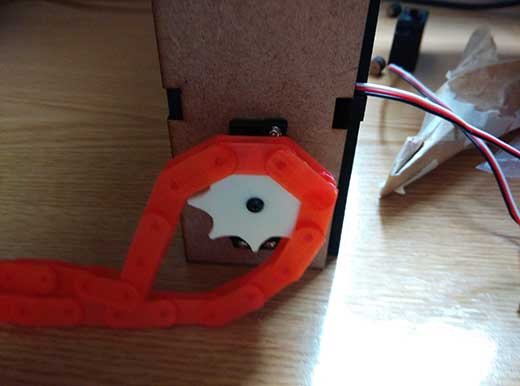

2. Chain: the chain was a very early design that I thought it could work perfectly with this project. It is a very important piece of this project, as every single shackle has the size to fit in the gears. 3D printing the chain was a very smart idea, because the machine will give me the chain already assembled. 3. Gears: the gears have different uses in the final project, but all of them are used to controll the chain through the facade of the "building". This gears were done with the Molding and Casting assignment. My initial design did not have a level change of the mechanics, but I found more interesting to put the servo in a differnt level of the rest of the gears in order to do some additional work and think further about the mechanics of my project. 4. Louvers: even though the louvers are not ready yet, I have the design on 3D ready to do the Molding and Casting. This piece will have a very strong importance and will developed into two molds, and I will insert all along the mold a piece of round dipstick so it fits perfectly and gives me an assembled piece of louver. |

Assembling the mechanics For this week I just approached to my final model trying to see if the chain is supporting enough the forces that the servo and the gears do. Some additional pieces as some locks at each side of the wood structure were added in order to maintain the dipstick fixed and not moving longitudinally. For this week I will design and 3D print an specific piece for each of the sides so I can screw the piece into the wood and maintain the dipstick fixed. There are several pieces that will help the assembly, so I will keep trying to develop more and more the project in the following weeks.

|

|

Testing the model The final step of the assignement was actually to test the model and see how it is working. These are some videos that I recorded to seethe result. |

|